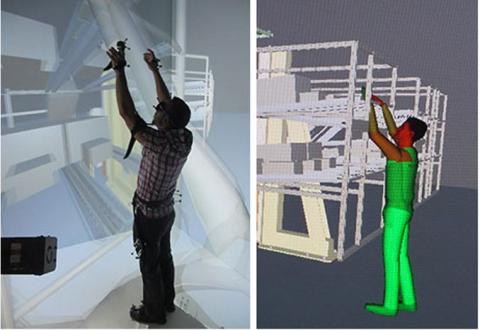

Wilo uses virtual reality for the ergonomic design of its new production lines

For six years, WILO has managed to divide by 10 the number of days off work for occupational diseases (MSDs) and to reduce nursing care by 45% following MSDs thanks to their proactive approach to optimizing working conditions. “Ergo+” work.

In this context, from the design phase of their new workstations, WILO uses the “Ergowide3” virtual reality solution developed by CLARTE and operated by AF’ergo Conseil to simulate and improve work postures in real time even before the machine is actually built: “The goal is to do it right the first time. Virtual reality makes it possible to rethink an operation if it is not ergonomic. As we are in “anticipation” mode, and not “reaction”, ergo-design is a real advantage”.